New Opportunities for Collaboration

In an era of shifting global supply chains and evolving trade dynamics, Thailand’s lighting manufacturing sector has emerged as a pivotal link for businesses aiming to access the U.S. market. With its strategic location, competitive production costs, and robust trade partnerships, Thailand is positioning itself as a critical node in the global supply chain—one that offers unique advantages for companies navigating the complexities of international commerce.

Thailand’s Rise as a Lighting Manufacturing Powerhouse

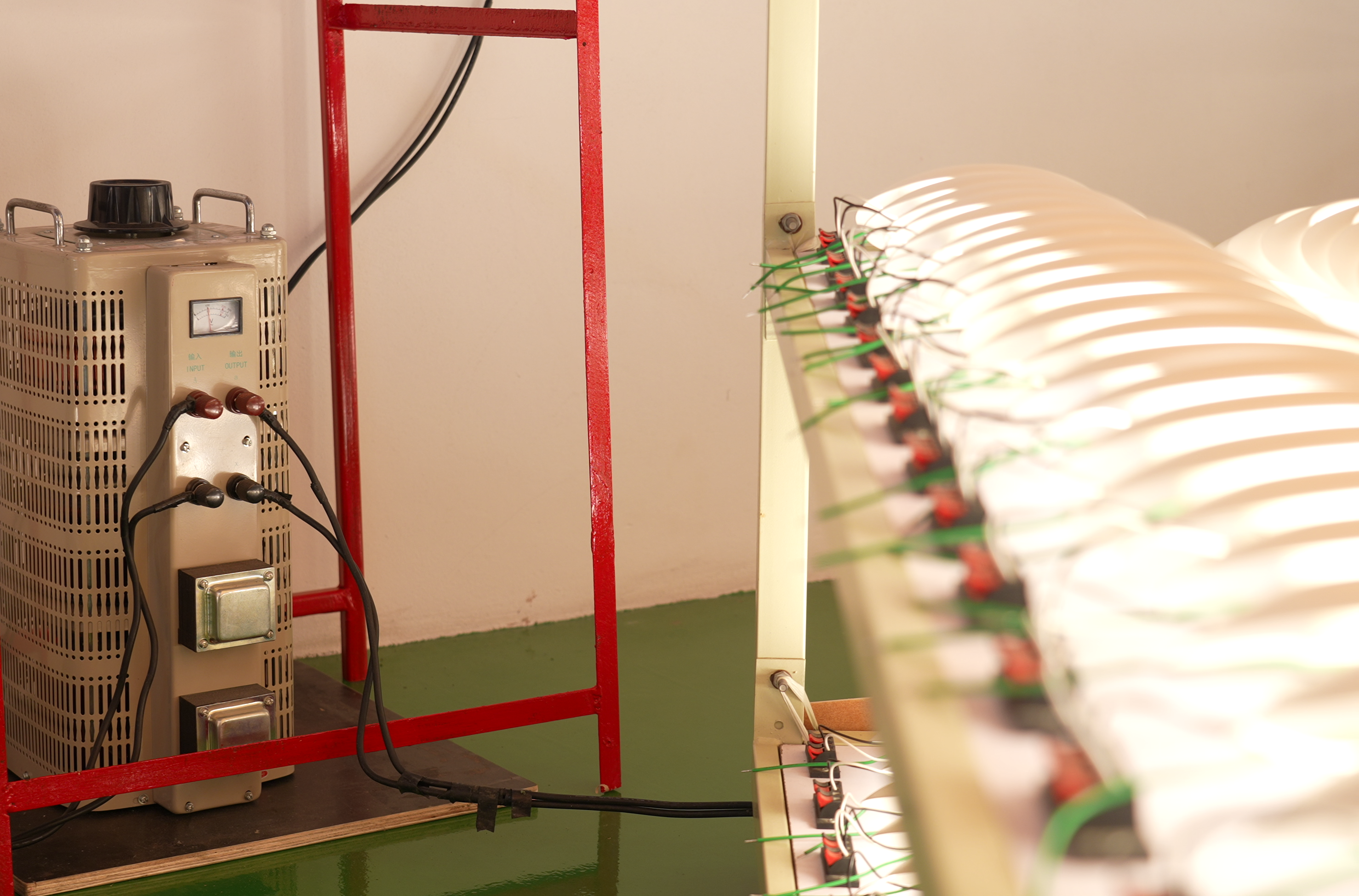

Thailand’s manufacturing ecosystem has long been recognized for its adaptability and innovation. The lighting industry, in particular, has seen significant growth, driven by investments in advanced technologies, skilled labor, and government incentives. Ledvast’s Thai factory specializes in producing a wide range of lighting products, from energy-efficient LED fixtures to smart lighting systems tailored to modern consumer demands. Key factors underpinning Thailand’s competitive edge include:

- Cost Efficiency: Lower labor and operational costs compared to Western markets, coupled with economies of scale, enable Ledvast’s Thai lighting factory to deliver high-quality products at competitive prices.

- Strategic Geography: Situated at the heart of Southeast Asia, Thailand offers seamless access to regional and global shipping routes, reducing lead times for exports to the U.S.

- Trade Agreements: Thailand’s participation in trade pacts such as the ASEAN-U.S. Trade and Investment Framework Agreement (TIFA) mitigates tariff barriers, enhancing the appeal of Thai-made goods.

Bridging the U.S. Market: Why Thailand Matters

For U.S. businesses, sourcing lighting products from Thailand addresses several challenges:

- Diversification of Supply Chains: Amid geopolitical tensions and disruptions, Thailand provides a stable alternative to traditional manufacturing hubs like China.

- Compliance with U.S. Standards: Ledvast’s Thai lighting factory increasingly adhere to stringent U.S. regulatory requirements, including energy efficiency certifications (e.g., ENERGY STAR) and safety standards (e.g., UL listing).

- Sustainability Focus: As U.S. consumers and regulators prioritize eco-friendly products, Thai manufacturers are investing in sustainable practices, such as solar-powered production facilities and recyclable materials.

Case Study: Success Through Collaboration

A notable example is the partnership between a Ledvast’s Bangkok-based lighting factory and several U.S. importers. By leveraging Thailand’s expertise in custom design and rapid prototyping, the US importers reduced time-to-market by 30% while maintaining cost margins. Additionally, the Ledvast’s Thai factory use of automation ensured consistent quality, earning the US importers accolades for product reliability.

Navigating Challenges

While opportunities abound, businesses must address potential hurdles:

- Logistics Optimization: Partnering with experienced freight forwarders and utilizing Thailand’s deep-sea ports (e.g., Laem Chabang) can streamline shipping to U.S. coastal hubs.

- Cultural and Regulatory Alignment: Engaging local consultants or joint ventures helps bridge communication gaps and ensures compliance with both Thai and U.S. trade laws.

The Road Ahead

Ledvast’s Thai lighting factory is poised for further growth, with projections indicating a 50% annual increase in exports to the U.S. over the next five years. For forward-thinking companies, collaboration with Ledvast’s Thai lighting factory represents not just a cost-saving strategy, but a pathway to innovation, resilience, and long-term market success.

In conclusion, as global supply chains redefine themselves, Thailand’s role as a connective hub between East and West has never been more vital. By tapping into this dynamic ecosystem, businesses can illuminate new opportunities—both literally and figuratively—in the ever-expanding U.S. market.