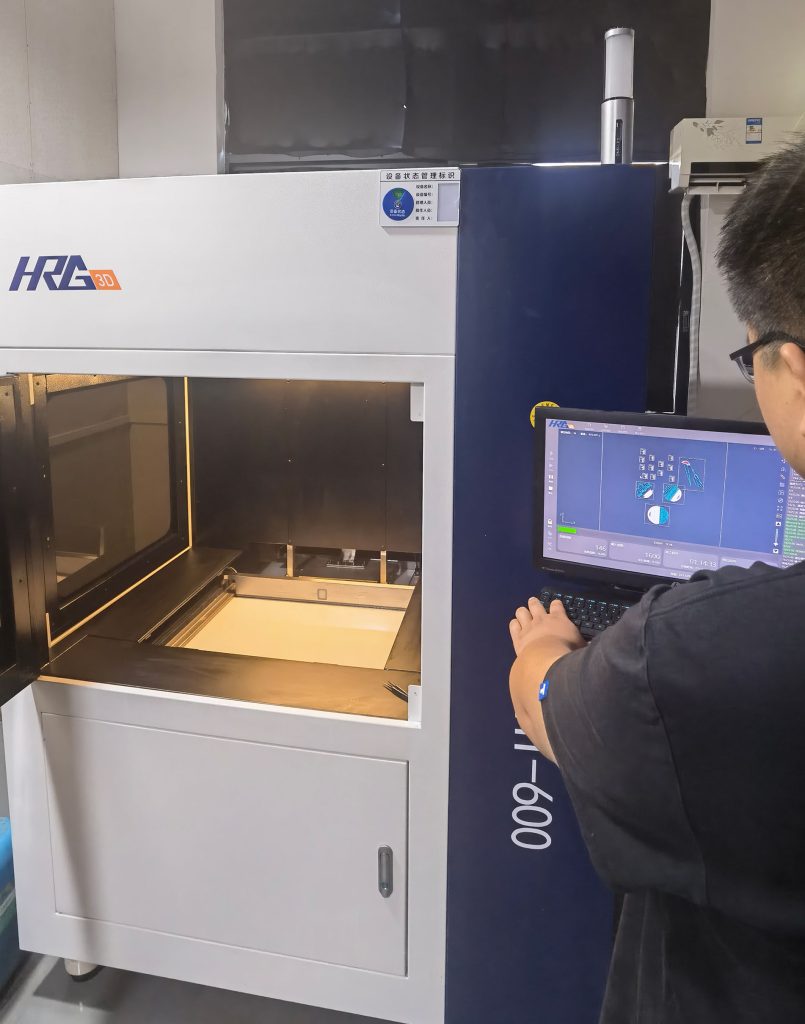

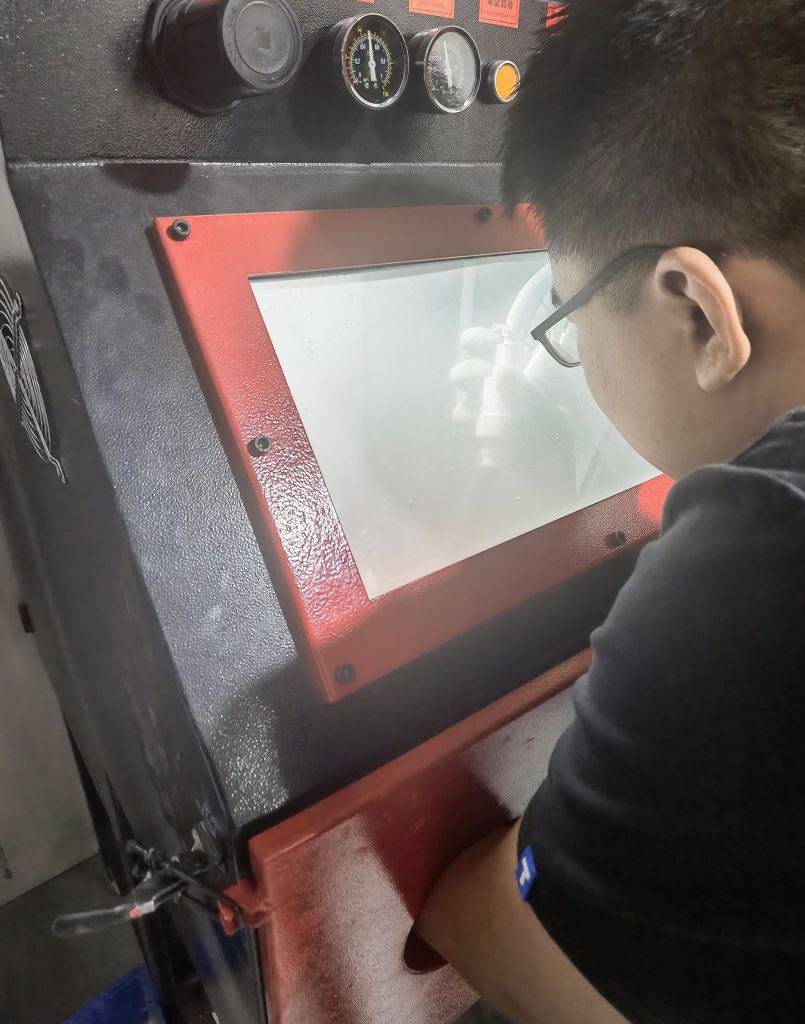

In order to provide accurate prototypes and components for both internal and customers’ evaluation purpose efficiently, we have set up industrial 3D printer in our China headquarter to enhance our engineering services.

In the lighting industry, innovation and personalization are key factors nowadays. With the rapid development of 3D printing technology, it is gradually becoming an important tool for lighting design and manufacturing. Whether it’s designers, manufacturers, or consumers, the flexibility, customization, and efficiency of 3D printers bring new possibilities to the lighting industry.

Traditional lighting manufacturing processes often restrict designers’ creativity in terms of shape, materials, and structures, while 3D printing technology breaks these limitations. Designers can transform their ideas into digital designs through 3D modeling software and then use 3D printers to bring them to life. From complex geometric shapes to unique textures and structures, 3D printers can accurately reproduce designers’ ideas, making each lighting fixture a unique piece of art.

Most importantly, 3D printing technology has great potential in sustainable development. Traditional lighting manufacturing often generates a large amount of waste and resource consumption, while 3D printers can minimize waste by precise printing according to needs. Additionally, using renewable materials for 3D printing can reduce environmental impact and promote the lighting industry towards sustainable development.